While daily and weekly tasks keep your Quad 800 running smoothly day to day, long-term maintenance is just as important. Checking for unusual noises, applying lubrication and inspecting mechanical parts can help you prevent breakdowns and extend the overall life of the machine.

Noise Inspection

Strange or irregular noises may be early signs of wear or loose parts. During long-term checks, power on the machine and listen carefully during operation. If you hear rattling, grinding or vibrations that are not normally present, investigate further or contact support if needed.

Lubricate Moving Parts

Some parts of the Quad 800, such as squeegee pulleys or rotating joints, may benefit from occasional lubrication. This reduces friction and helps those components move freely.

To apply lubrication:

-

Use a small amount of suitable machine grease

-

Apply it to joints, pulleys or any regularly rotating metal components

-

Wipe off excess to avoid attracting dust

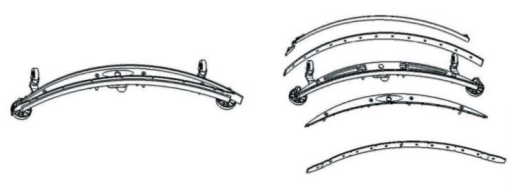

Check Squeegee Assembly

Inspect the entire squeegee mechanism, not just the rubber blade. Look for any loose screws, bent brackets or signs of damage. Also check the springs and sheet metal parts to make sure they are holding their shape and staying firmly in place during use.

Tank Seals and Hoses

Over time, the sealing ring on the water tank cover and the drain hoses may wear out. Check for cracks, leaks or looseness. If you find any air leaks or signs of damage, replace the affected parts promptly to avoid suction loss.

How Often to Do This

Perform these long-term maintenance tasks about once a month, or more frequently if the machine is in constant daily use. Listening carefully and inspecting parts regularly can help you catch small issues before they become major problems.